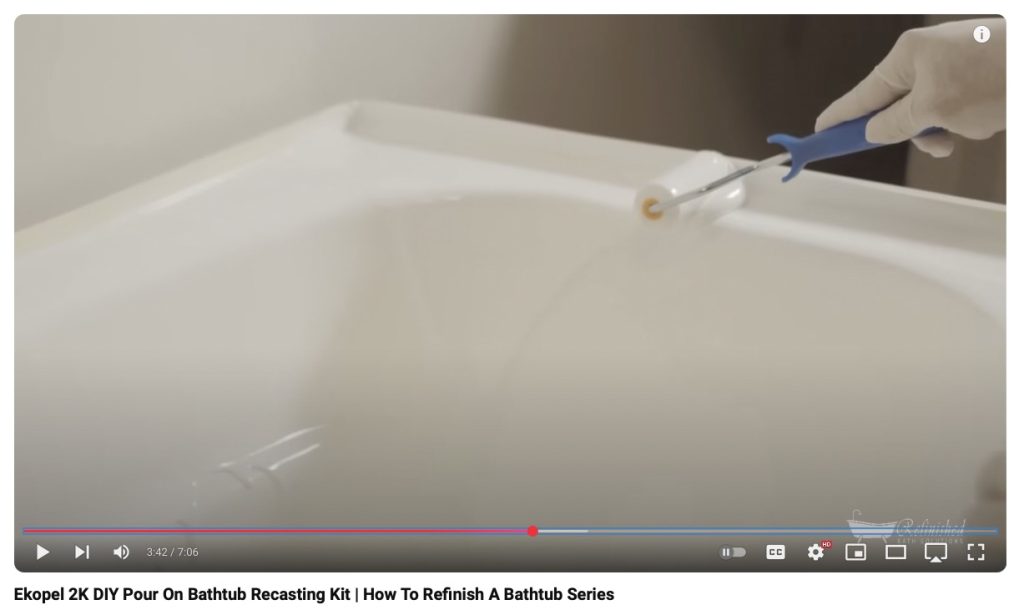

Video Reviewed:

“Ekopel 2K DIY Pour On Bathtub Recasting Kit”

Watch on YouTube

Timestamp: 3:42

Expert Evaluation: Public Demonstration Review

As part of my ongoing expert evaluations in the field of bathtub refinishing, I occasionally review public demonstrations and industry content to identify common mistakes and raise awareness of best practices. The following is an expert evaluation of a publicly available demonstration.

In this video, a technician demonstrates how to refinish a bathtub using a material (Ekopel 2K). However, several fundamental issues in this process compromise the long-term durability of the coating.

Problem #1: No Mechanical Surface Preparation

The tub surface in the video remains glossy and smooth before application. No mechanical sanding (with a grinder or power sander) is performed to roughen the surface.

Why it matters:

Without a properly abraded surface, the coating cannot create a strong bond. It will likely begin to peel or separate within a few months, especially under heat and moisture.

Just today, I removed a similar coating from a tub that had been refinished using this same technique. It peeled off easily, and the surface underneath was still perfectly smooth — proof that no proper adhesion was achieved.

Problem #2: Incorrect Application Method (Roller)

In the video, the technician uses a roller to apply the material.

Why it’s a mistake:

This type of material is designed for pour-on application. Using a roller leads to a very thin layer of coating, which lacks strength and wears down quickly.

My Recommendation:

- Always sand the tub with a grinder or power tool before application — a rough surface is essential for adhesion.

- Use the pour-on method as intended by the manufacturer — it ensures proper layer thickness and durability.

- Allow the tub to cure in a stable environment with proper ventilation.

Final Thoughts:

Refinishing a bathtub is not just about appearance — it’s about longevity, adhesion, and safety. Shortcuts in preparation and application may look good on video, but they fail in real life.

If you’re a homeowner considering refinishing — or a technician learning the craft — make sure the process is done right from the beginning.

—

Evaluation Summary:

This article is part of a professional series of evaluations authored by Artem Tugbaev, intended to analyze and judge the quality of bathtub refinishing techniques demonstrated by others in the industry. The criteria for evaluation include surface preparation, application method, material compatibility, and durability potential.